Firmly rooted in the idyllic countryside in Suffolk, Pump Street has fast become a destination for excellent sourdough and chocolate. Their claim to fame in the world of chocolate has to be their Sourdough and Sea Salt Chocolate Bar.

The Chocolate Bakery Series is true to their identity as bakers and chocolate makers. Their recent ones even incorporate croissant, rye crumb and Eccles cake.

The Pump Street chocolate shop across the café in Orford.

Pump Street was initially planned to be part of the Piura Blanco Cacao Documentary. Plans changed however. Chris Brennan who co-founded the company with his daughter, Joanna Brennan, uses the rare albino cacao. In fact, it’s Don Ramon’s beans that are used for their 72% Peru bar.

Two years later after that first phone call with Chris we finally made the journey out of London to England’s beautiful heritage coast. We needed nature, exercise and good chocolate. We packed our bikes and as spontaneous as we are hopped on the next outbound train to Ipswich.

From Ipswich, it’s about 2 hours in the saddle to Pump Street. The plan was to cycle from Woodbridge as it is 1 hour, but we missed our connecting train (they are as unreliable here as the Great British Summer).

Once we hit the quiet country lanes we encountered friendly locals, caught a sobering scent of dung and the mid-morning sun was smiling down at us.

We met Chris at the cafe and sat down to what has to be the most delicious chocolate brownie and hot chocolate we have ever tasted. Bold claim, I know. It was probably fresh country air, cycling and meeting Chris that gave us such great joy as well.

The brownie was made with 70% dark chocolate from Grenada. It was heavenly light. The 85% hot chocolate from Ecuador had deep toffee notes and toasted walnut. What a treat!

Over hot chocolate and coffee Chris told us a bit about his background and early baking and chocolate making days. Highly interesting is his education in Chemistry. He started making chocolate because he realised that the bacteria in baking and cacao are exactly the same. They influence the flavour in the fermentation process.

On the Pump Street blog you can read about a bakery-style starter being introduced to the cacao fermentation process in Jamaica. It allows for more control in flavour balance and consistency in the final bar of chocolate. The full article can be found here.

Just opposite the café is the official chocolate shop. Andrew is the keeper of the bars and let us sample some of the new Bakery Series.

Our personal favourite was the Rye Crumb, Milk & Sea Salt 60%. It has a great crunch and flavour profile. Expect notes of Malted Grain and Creme Brûlée. The sea salt used in this bar is sourced from Wales and has its own geographical protection like Parma Ham or Champagne.

Part two of our chocolate adventure included a tour of the factory. Located 40 minutes by bike close to Rendlesham, we crossed a no-go derelict airfield, which served to carry nuclear bombs to Germany during the Cold War. Security was so kind and escorted us directly to Pump Street, otherwise it would have meant cycling around the entire airfield.

The way the factory is set up is very clever. Beans arrive in the above container, enter one way and travel through the factory in a circular path emerging out the other end in a lovingly wrapped bar of chocolate.

1000 Kg of chocolate is produced every week and 15 people work at any one time to make it. In total 25 chocolate makers are employed here.

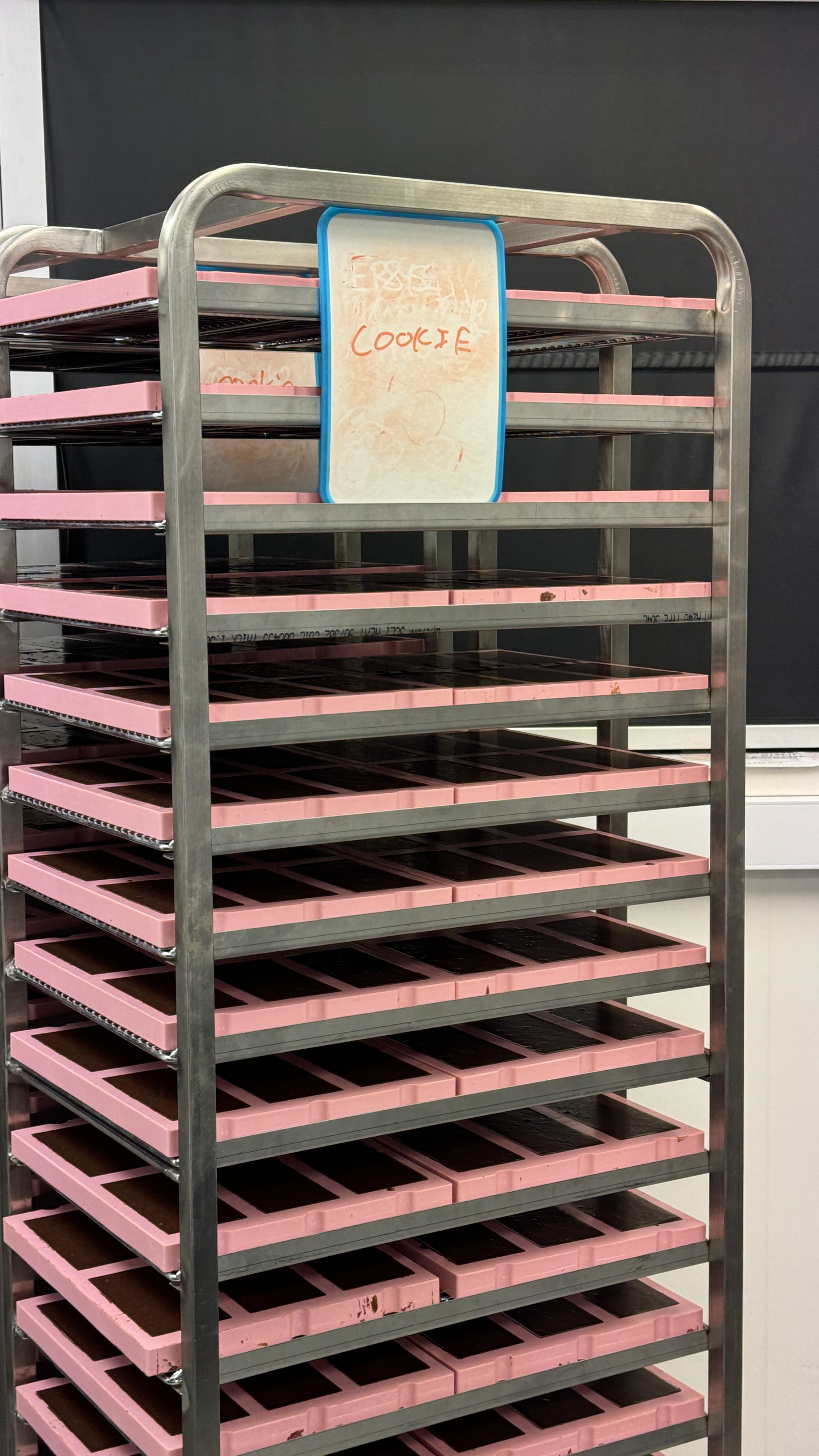

The first step in the production pipeline is hand-sorting the beans. Afterwards they are loaded onto trays and steam-roasted for 3 minutes. About 1.6 Kg per tray. The steaming technique softens the shell of the beans and releases the acids. It is a concept from the 80s. Also the ovens are baking ovens and therefore true to their nature as bakers.

Chris told us that all the big companies (like Cadbury’s) had already invested in conventional roasting equipment back then, otherwise they would have utilised this way of roasting as well.

Afterwards, the beans are ground, winnowed and turned into cacao liquor. At this stage the chocolate is left to rest for 1 month before being handed over to the conching and tempering team. This allows for the acids in the chocolate to fully dissipate.

The conching room features a whopping 11 melangers running at the same time.

Conching & Tempering.

Here they even make their own cacao butter, which is used for their white chocolate bars. The process is simple. The beans are pressed under intense pressure and you are left with cocoa butter and cocoa powder. In order to use the cocoa powder it would require further refining.

The cocoa butter press.

Once tempered the chocolate is fed into a syringe system. The machine fills the exact amount of chocolate into every mould down to the microgram.

After the moulds go into a cooling room the final step is packaging. The system for it was upgraded beginning of the year and ushered in the new pink design. Packing the bars now is a cinch! It is fully automated thanks to the Dutch technology company Lareka.

In the past, Pump Street used a ziplock style bag for their tablets. This required too many steps and now was the time to step up the game.

There may be a chance to return when production is in full swing and document more of the chocolate making process. I would love to share the packaging and filling of the moulds with you next time. In which case I will put together a new post with more info for you to enjoy.

Let me know if you are planning a visit to Pump Street, have any questions about our visit or need tips on train and bike travel to Orford. Just leave a comment below and I’ll happily get back to you.

Until then, I wish you a beautiful weekend with excellent chocolate.

Robin

Leave a comment